Pulsarlube M

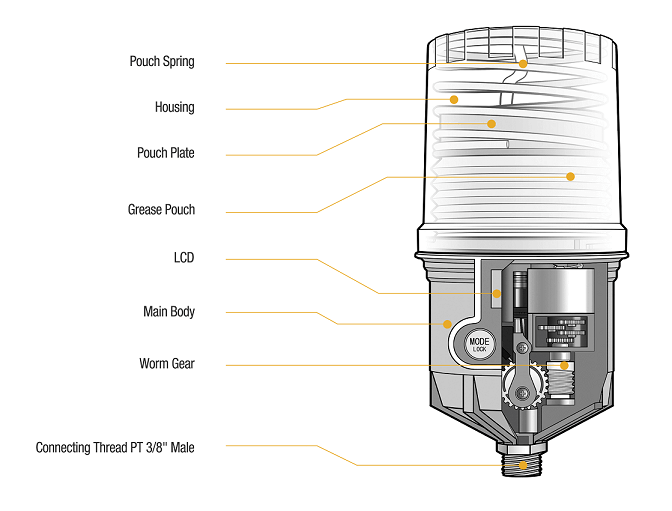

De Pulsarlube M bestaat uit een verticale plunjerpomp en een microprocessor, die zorgen voor een gemiddelde werkdruk van 30-60 bar (435-745 psi). De unit is ontworpen om betrouwbare smering te garanderen en tegelijkertijd smeerkosten te verlagen met kostenbesparende servicepacks.

Ontdek meer over de Pulsarlube M

Product bestellen

30kgf/cm²

Up to 8 lube points for multi-point installation. Max. 10m (30ft) for single point.

-40 °C

Optional Lithium Battery Pack available for low temperature usage.

LCD

Easy to program with built-in LCD and simple button controls.

Service Pack

Substantial savings from the use of replaceable grease pouches and battery packs.

Pulsarlube M Series 60, 125, 250, 500

De automatische elektromechanische vetsmeerunit Pulsarlube M is primair ontworpen om de prestaties van een conventionele, automatische vetsmeerunit van het gas- en elektrochemische type te compenseren. Het apparaat is bovendien veel kosteneffectiever en gebruiksvriendelijker dan vergelijkbare producten.

De Pulsarlube M bestaat uit een verticale zelfaanzuigende pomp, een microprocessorregelsysteem en een groot LCD-scherm. Dit product is ideaal voor toepassingen waarbij een aanzienlijke tegendruk in de smeermiddelleiding aanwezig is, een nauwkeurige smering vereist is of een wegwerpsmeerapparaat van het gas- en elektrochemische niet economisch is.

Product dimensies

- M60: Ø91 mm (3.60”) x 181 mm (7.13”) (H)

- M125: Ø91 mm (3.60”) x 181 mm (7.13”) (H)

- M250: Ø91 mm (3.60”) x 210 mm (8.27”) (H)

- M500: Ø92 mm (3.62”) x 260 mm (10.23”) (H)

![]()

Technische specificaties

| Specificatie | Waarde |

|---|---|

| Grease Pouch Capacity | 60ml/125ml/250ml/500ml (replaceable) |

| Remote Installation | Max. 10m (30ft) with O.D. Ø6mm tube |

| Power Supply | DC 4.5V Battery Pack |

| Multi-Point Installation | Max. 6m (20ft) with O.D. Ø6mm tube (Max. 8 lube points) |

| Operating Pressure | 30~60kgf/cm² (425psi~850psi) |

| Packaging | 10 Units/Case |

| Operating Temperature (Standard Alkaline Battery) | -15°C~60°C (5°F~140°F) |

| Operating Temperature (Optional Lithium Battery) | -40°C~60°C (-40°F~140°F) |

| Dispensing Periods (60ml) | 1,2,3…10,11,12 month |

| Dispensing Periods (125ml/250ml) | 1, 2, 3, 6, 12 month & H (15 days) |

| Dispensing Periods (500ml) | 1, 2, 4, 6, 12, 18, 24 month & H (15 days) |

![]()

Productcertificaten

| Certificaat | Waarde |

|---|---|

| IP code | IP54 |

| CE/Etc. | CE(CoC) |

Accesoires

Reducer, 3/8Part No.: A001

Reducer, 3/8Part No.: A002-S

Reducer, 3/8Part No.: A002

Socket, 1/4Part No.: A011

Socket, 1/8"F x 1/8"F Adaptor (Brass)Part No.: A012

90° Elbow, 1/4"F x 1/4"F Adaptor (Brass)Part No.: A019

90° Elbow, 1/8"F x 1/8"F Adaptor (Brass)Part No.: A020

90° Elbow, 1/4"M x 1/4"F Adaptor (Brass)Part No.: A021

90° Elbow, 1/8"M x 1/8"F Adaptor (Brass)Part No.: A022

45° Elbow, 1/4"M x 1/4"F Adaptor (Brass)Part No.: A023

45° Elbow, 1/8"M x 1/8"F Adaptor (Brass)Part No.: A024

Pipe, 1/8"M x 1/8"M x 50mm for divider block (Steel)Part No.: A106

Pipe, 1/8"M x 1/8"M x 100mm for divider block (Steel)Part No.: A107

Pipe, 1/8"M x 1/8"M x 150mm for divider block (Steel)Part No.: A108

Pipe, 1/8"M x 1/8"M x 200mm for divider block (Steel)Part No.: A109

Pipe, 1/4"M x 1/4"M x 50mm for divider block (Steel)Part No.: A121

Pipe, 1/4"M x 1/4"M x 100mm for divider block (Steel)Part No.: A122

Pipe, 1/4"M x 1/4"M x 150mm for divider block (Steel)Part No.: A123

Pipe, 1/4"M x 1/4"M x 200mm for divider block (Steel)Part No.: A124

Distribution Tubing, O.D. 5/16" (8mm) Urethan Tubing, 3ft Pre-filled with (Grease Type)Part No.: A212-1

Tube Fitting, Push-In Type, PC8-PT1/8"MPart No.: A239

Mounting Bracket, "L" ShapePart No.: B002

Self Drilling Screw, #8 x 20Part No.: B051

WasherPart No.: B057

Thread Converter, PT1/8"F x NPT1/8"M (Brass)Part No.: A243

![]()

Toepassingen

Power Plant

- Water Pumps

- Conveyor Systems

- Electric Motors

- Boilers

Steel Industry

- Conveyor Systems for coke, iron ore, and limestone

- Electric Motors

- Pumps

- Blowers and Fans

Cooling Towers

- Pans

- Blowers

- Pumps

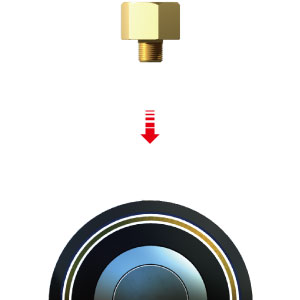

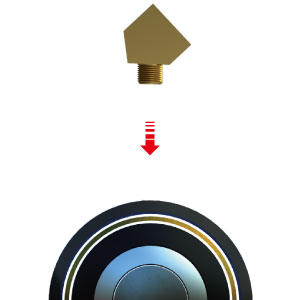

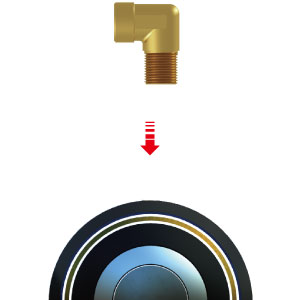

Directe montage installatie

Reducer

| Type | Waarde |

|---|---|

| A001 | Reducer, 3/8″F X 1/4″M Adaptor (Brass) |

| A002 | Reducer, 3/8″F X 1/8″M Adaptor (Brass) |

| A003 | Reducer, 3/8″F x 1/8″M Adaptor (Steel) |

45˚ Elbow

| Type | Waarde |

|---|---|

| A023 | 45° Elbow, 1/4”M X 1/4”F Adaptor (Brass) |

| A024 | 45° Elbow, 1/8”M X 1/8”F Adaptor (Brass) |

90˚ Elbow

| Type | Waarde |

|---|---|

| A019 | 90° Elbow, 1/4”F X 1/4”F Adaptor (Brass) |

| A020 | 90° Elbow, 1/8”F X 1/8”F Adaptor (Brass) |

| A021 | 90° Elbow, 1/4”M X 1/4”F Adaptor (Brass) |

| A022 | 90° Elbow, 1/8”M X1/8”F Adaptor (Brass) |

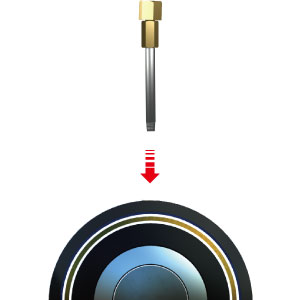

Socket + Pipe + Reducer

| Type | Waarde |

|---|---|

| A011 | Socket, 1/4″F x 1/4″F Adaptor (Brass) |

| A012 | Socket, 1/8″F x 1/8″F Adaptor (Brass) |

| A121 | Pipe,1/4”M X 1/4”M × 50mm (Steel) |

| A122 | Pipe,1/4”M X 1/4”M × 100mm (Steel) |

| A123 | Pipe,1/4”M X 1/4”M × 150mm (Steel) |

| A124 | Pipe,1/4”M X 1/4”M × 200mm (Steel) |

| A106 | Pipe, 1/8″M x 1/8″M x 50mm for divider block (Steel) |

| A107 | Pipe, 1/8″M x 1/8″M x 150mm for divider Pipe, 1/8″M x 1/8″M x 100mm for divider block (Steel) |

| A108 | Pipe, 1/8″M x 1/8″M x 150mm for divider block (Steel) |

| A109 | Pipe, 1/8″M x 1/8″M x 200mm for divider block (Steel) |

Single point remote installation

Kit No. 2000RC-1

| Type | Waarde |

|---|---|

| A005 | Reducer, 1/4″F x 1/8″ M Adaptor (Brass) |

| B002 | Mounting Bracket, “L”Shape |

| B051 | Self Drilling Screw, #8ⅹ20 |

| B057 | Washer |

| A012 | Socket, 1/8”F x 1/8”F Adaptor (Brass) |

| A239 | Tube Fitting, Push-In Type, PC8-PT1/8″M |

| A212-1 | Distribution Tubing, O.D. 5/16″(8mm). Urethan Tubing, 3ft Pre-filled with (Grease Type) |

| A243 | Thread Converter, PT1/8″F X NPT1/8″M (Brass) |

Note : For remote installation using a tube, use an 8mm O.D. (5/16″) tubing pre-filled with the same or compatible grease as the grease contained in the unit. Recommend using under short dispensing period settings due to powerful dispensing pressure.

Multi-Point installation

Electromechanical Products using a divider block ( up to 8 points )

Comments